Stepper Motor Core

Yuma Precision is a company specializing in the production of motor cores. Through our diverse range of Motor Core products, we are dedicated to providing users with a rich selection and exceptional product experience. We have the capability to design and manufacture custom Motor Cores based on specific requirements and dimensions provided by you.

From the perspective the difficulty of stamping process of stator and rotor core, the production scheme of the stepper motor iron core stamping is undoubtedly one of the series with the highest comprehensive difficulty in the stamping industry. Under the condition that the stamping production of stator and rotor is carried out through zero clearance, the product can achieve rotary lamination at the same time, and finally achieve the micro interference state of stator and rotor, which not only reduces the cost but also meets the needs of customers for the amount of motor wear; And the product after rotation from the form and position tolerance, motor performance has been improved significantly. Yuma Precision continues to advance the development of stepper series. At present, it has 9 series, 33 models and more than 10,000 pieces of materials, providing sufficient model selection for stepper motor standard parts market.

The stator adopts the combined structure of tooth and yoke, which greatly reduces the production cost of iron core compared with the conventional segment structure. In the design of the rotor, the magnetic steel structure adopts IPM structure. Compared with the conventional SPM structure, the cost of the magnetic steel is reduced synchronously. Moreover, the stator and rotor punched from one die, and the cost of a set of iron core is reduced by more than 15% compared with the previous scheme.

The stator adopts the combined structure of tooth and yoke, which greatly reduces the production cost of iron core compared with the conventional segment structure. In the design of the rotor, the magnetic steel structure adopts IPM structure. Compared with the conventional SPM structure, the cost of the magnetic steel is reduced synchronously. Moreover, the stator and rotor punched from one die, and the cost of a set of iron core is reduced by more than 15% compared with the previous scheme.

New energy vehicles are undoubtedly the direction of the follow-up development of the automotive industry, and Yuma Precision Intelligent Manufacturing Park has injected sufficient power into the new energy industry; At present, we have dabbled in all kinds of automotive pump, automotive rotary transformers, air conditioning compressor, electric hydraulic pump, EPS steering motor, power motor, pure electric/hybrid drive motor, rocking window motor and other automotive fields. In the future, we will devote more energy to acceleratinge the global manufacturing and achieve a green future.

New energy vehicles are undoubtedly the direction of the follow-up development of the automotive industry, and Yuma Precision Intelligent Manufacturing Park has injected sufficient power into the new energy industry; At present, we have dabbled in all kinds of automotive pump, automotive rotary transformers, air conditioning compressor, electric hydraulic pump, EPS steering motor, power motor, pure electric/hybrid drive motor, rocking window motor and other automotive fields. In the future, we will devote more energy to acceleratinge the global manufacturing and achieve a green future.

To boost the development of industrial automation industry, servo motor is an indispensable key point. In the matching of servo motor, Yuma precision has corresponding solutions from sample to mass production. From the perspective of performance, the sample made by engineering tooling is comparable to the standard of mass production, , which provides a good proofing scheme and platform for customer's R & D and trial production; From the perspective of mass production, we provide customers with the most appropriate mass production solutions by measuring product technical requirements and cost plans.

To boost the development of industrial automation industry, servo motor is an indispensable key point. In the matching of servo motor, Yuma precision has corresponding solutions from sample to mass production. From the perspective of performance, the sample made by engineering tooling is comparable to the standard of mass production, , which provides a good proofing scheme and platform for customer's R & D and trial production; From the perspective of mass production, we provide customers with the most appropriate mass production solutions by measuring product technical requirements and cost plans.

Length: 181.72mm

Height: 50mm

Pole number: 6

The linear motor core is usually composed of silicon steel sheets. The main function of silicon steel sheets is to reduce magnet losses and eddy current losses. Silicon steel sheets have good magnetic permeability and low magnetic permeability, which can effectively conduct magnetism and reduce energy loss in linear motors. Silicon steel sheets are usually stacked, bonded, and processed to ensure the efficient operation of linear motors. Parameters such as the thickness and magnetic permeability of the silicon steel sheet are selected according to the design requirements of the linear motor to ensure the performance and efficiency of the motor.

Linear motor cores are widely used in electronic and semiconductor equipment, photovoltaic lithium battery industry, UV inkjet printing industry, precision CNC machine tools, high-end medical equipment, mobile phone testing industry, glass testing industry and other fields.

Length: 181.72mm

Height: 50mm

Pole number: 6

The linear motor core is usually composed of silicon steel sheets. The main function of silicon steel sheets is to reduce magnet losses and eddy current losses. Silicon steel sheets have good magnetic permeability and low magnetic permeability, which can effectively conduct magnetism and reduce energy loss in linear motors. Silicon steel sheets are usually stacked, bonded, and processed to ensure the efficient operation of linear motors. Parameters such as the thickness and magnetic permeability of the silicon steel sheet are selected according to the design requirements of the linear motor to ensure the performance and efficiency of the motor.

Linear motor cores are widely used in electronic and semiconductor equipment, photovoltaic lithium battery industry, UV inkjet printing industry, precision CNC machine tools, high-end medical equipment, mobile phone testing industry, glass testing industry and other fields.

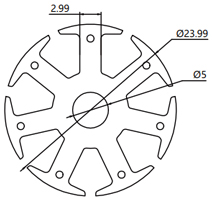

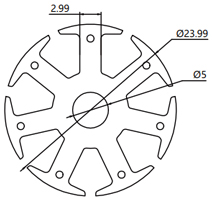

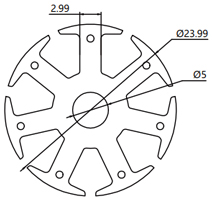

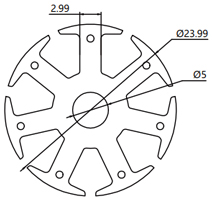

OD24mm Brushless Bldc motor rotor and stator laminated iron core stamping DC for Industrial control

Stator OD | Stator ID | Number of slots |

| 24mm | 5mm | 7 |

Pole width | Material | Height |

| 3mm | B50A600 | 30mm / 40mm / customized |

OD24mm Brushless Bldc motor rotor and stator laminated iron core stamping DC for Industrial control

Stator OD | Stator ID | Number of slots |

| 24mm | 5mm | 7 |

Pole width | Material | Height |

| 3mm | B50A600 | 30mm / 40mm / customized |

Generally speaking, the role of core injection molding is to comprehensively protect, insulate and improve the overall performance of the motor, making it more suitable for operation in different environments and working conditions. This process is usually used for core protection in motors, transformers and other equipment to ensure long-term stable operation of the equipment.

Generally speaking, the role of core injection molding is to comprehensively protect, insulate and improve the overall performance of the motor, making it more suitable for operation in different environments and working conditions. This process is usually used for core protection in motors, transformers and other equipment to ensure long-term stable operation of the equipment.

New energy / automotive motor cores, Yuma Precision currently has rich project experience in the development of automotive motor cores. At the same time, we have cooperated in the development of new energy pure electric/hybrid vehicle drive motors, compressor cores, and automotive power steering motors, automobile oil pump motor core, window motor core and other dozens of automotive products. It has rich experience in cooperation and development, and combines iron cores with rubber-coated parts to optimize the product structure.

New energy / automotive motor cores, Yuma Precision currently has rich project experience in the development of automotive motor cores. At the same time, we have cooperated in the development of new energy pure electric/hybrid vehicle drive motors, compressor cores, and automotive power steering motors, automobile oil pump motor core, window motor core and other dozens of automotive products. It has rich experience in cooperation and development, and combines iron cores with rubber-coated parts to optimize the product structure.

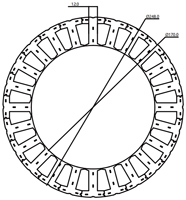

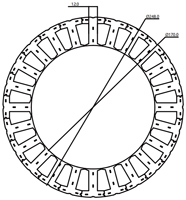

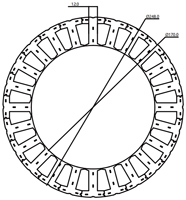

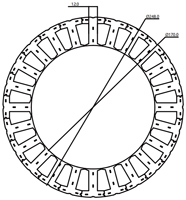

248mm OD High quality industrial motor rotor and stator laminated iron core for Textile machine

| Outer diameter | Inner diameter | Pole width |

| 248mm | 170mm | 12mm |

| Number of slot | Skeleton | Material |

| 24 | NO | B35A300H |

Compared with the traditional structure, it is characterized by the direct drive structure, which can reduce the energy saving of the motor by more than 20%.

248mm OD High quality industrial motor rotor and stator laminated iron core for Textile machine

| Outer diameter | Inner diameter | Pole width |

| 248mm | 170mm | 12mm |

| Number of slot | Skeleton | Material |

| 24 | NO | B35A300H |

Compared with the traditional structure, it is characterized by the direct drive structure, which can reduce the energy saving of the motor by more than 20%.

New energy vehicles are undoubtedly the direction of subsequent development of the automotive industry. Yuma Precision Intelligent Manufacturing Park has injected sufficient power into the new energy industry; currently we have been involved in various types of automotive pumps, automotive spindles, air conditioning compressors, electro-hydraulic pumps, and EPS steering. Motors, booster motors, pure electric/hybrid drive motors, window motors and other automotive fields. In the future, we will devote more energy to accelerating global manufacturing and achieving a green future.

At present, Yuma is involved in the automotive field → pure electric drive motor, hybrid P1/P2/P3 drive motor, automotive water pump/oil pump motor, EPS steering motor, gear selector motor, compressor, window motor

New energy vehicles are undoubtedly the direction of subsequent development of the automotive industry. Yuma Precision Intelligent Manufacturing Park has injected sufficient power into the new energy industry; currently we have been involved in various types of automotive pumps, automotive spindles, air conditioning compressors, electro-hydraulic pumps, and EPS steering. Motors, booster motors, pure electric/hybrid drive motors, window motors and other automotive fields. In the future, we will devote more energy to accelerating global manufacturing and achieving a green future.

At present, Yuma is involved in the automotive field → pure electric drive motor, hybrid P1/P2/P3 drive motor, automotive water pump/oil pump motor, EPS steering motor, gear selector motor, compressor, window motor

Complete in specifications NEMA14-NEMA34 Welcome to inquire

Yuma Precision continues to develop stepper series products, currently including 14 / 20 / 28 / 35 / 36 / 39 / 42 / 57 / 60 / 86 series. Provide customers with ample model choices.

By using rotary lamination, the problem of the same plate difference on the material is eliminated, and the parameters such as the parallelism, flatness and the dynamic balance of the rotor with lateral run out of the product can reach the ideal effect of the customer. At present, and the annual production is nearly 35 million sets. More than 300 customers choose and build long-term and stable relationship with Yuma.

In the research and development of new products, Yuma will continue to optimize the tooth shape / groove type / inner hole of products accordin

Complete in specifications NEMA14-NEMA34 Welcome to inquire

Yuma Precision continues to develop stepper series products, currently including 14 / 20 / 28 / 35 / 36 / 39 / 42 / 57 / 60 / 86 series. Provide customers with ample model choices.

By using rotary lamination, the problem of the same plate difference on the material is eliminated, and the parameters such as the parallelism, flatness and the dynamic balance of the rotor with lateral run out of the product can reach the ideal effect of the customer. At present, and the annual production is nearly 35 million sets. More than 300 customers choose and build long-term and stable relationship with Yuma.

In the research and development of new products, Yuma will continue to optimize the tooth shape / groove type / inner hole of products accordin

Inquiry Now

Inquiry NowFrom the perspective the difficulty of stamping process of stator and rotor core, the production scheme of the stepper motor iron core stamping is undoubtedly one of the series with the highest comprehensive difficulty in the stamping industry. Under the condition that the stamping production of stator and rotor is carried out through zero clearance, the product can achieve rotary lamination at the same time, and finally achieve the micro interference state of stator and rotor, which not only reduces the cost but also meets the needs of customers for the amount of motor wear; And the product after rotation from the form and position tolerance, motor performance has been improved significantly. Yuma Precision continues to advance the development of stepper series. At present, it has 9 series, 33 models and more than 10,000 pieces of materials, providing sufficient model selection for stepper motor standard parts market.

The stator adopts the combined structure of tooth and yoke, which greatly reduces the production cost of iron core compared with the conventional segment structure. In the design of the rotor, the magnetic steel structure adopts IPM structure. Compared with the conventional SPM structure, the cost of the magnetic steel is reduced synchronously. Moreover, the stator and rotor punched from one die, and the cost of a set of iron core is reduced by more than 15% compared with the previous scheme.

Inquiry Now

Inquiry Now

The stator adopts the combined structure of tooth and yoke, which greatly reduces the production cost of iron core compared with the conventional segment structure. In the design of the rotor, the magnetic steel structure adopts IPM structure. Compared with the conventional SPM structure, the cost of the magnetic steel is reduced synchronously. Moreover, the stator and rotor punched from one die, and the cost of a set of iron core is reduced by more than 15% compared with the previous scheme.

New energy vehicles are undoubtedly the direction of the follow-up development of the automotive industry, and Yuma Precision Intelligent Manufacturing Park has injected sufficient power into the new energy industry; At present, we have dabbled in all kinds of automotive pump, automotive rotary transformers, air conditioning compressor, electric hydraulic pump, EPS steering motor, power motor, pure electric/hybrid drive motor, rocking window motor and other automotive fields. In the future, we will devote more energy to acceleratinge the global manufacturing and achieve a green future.

Inquiry Now

Inquiry Now

New energy vehicles are undoubtedly the direction of the follow-up development of the automotive industry, and Yuma Precision Intelligent Manufacturing Park has injected sufficient power into the new energy industry; At present, we have dabbled in all kinds of automotive pump, automotive rotary transformers, air conditioning compressor, electric hydraulic pump, EPS steering motor, power motor, pure electric/hybrid drive motor, rocking window motor and other automotive fields. In the future, we will devote more energy to acceleratinge the global manufacturing and achieve a green future.

To boost the development of industrial automation industry, servo motor is an indispensable key point. In the matching of servo motor, Yuma precision has corresponding solutions from sample to mass production. From the perspective of performance, the sample made by engineering tooling is comparable to the standard of mass production, , which provides a good proofing scheme and platform for customer's R & D and trial production; From the perspective of mass production, we provide customers with the most appropriate mass production solutions by measuring product technical requirements and cost plans.

Inquiry Now

Inquiry NowTo boost the development of industrial automation industry, servo motor is an indispensable key point. In the matching of servo motor, Yuma precision has corresponding solutions from sample to mass production. From the perspective of performance, the sample made by engineering tooling is comparable to the standard of mass production, , which provides a good proofing scheme and platform for customer's R & D and trial production; From the perspective of mass production, we provide customers with the most appropriate mass production solutions by measuring product technical requirements and cost plans.

Length: 181.72mm

Height: 50mm

Pole number: 6

The linear motor core is usually composed of silicon steel sheets. The main function of silicon steel sheets is to reduce magnet losses and eddy current losses. Silicon steel sheets have good magnetic permeability and low magnetic permeability, which can effectively conduct magnetism and reduce energy loss in linear motors. Silicon steel sheets are usually stacked, bonded, and processed to ensure the efficient operation of linear motors. Parameters such as the thickness and magnetic permeability of the silicon steel sheet are selected according to the design requirements of the linear motor to ensure the performance and efficiency of the motor.

Linear motor cores are widely used in electronic and semiconductor equipment, photovoltaic lithium battery industry, UV inkjet printing industry, precision CNC machine tools, high-end medical equipment, mobile phone testing industry, glass testing industry and other fields.

Inquiry Now

Inquiry Now

Length: 181.72mm

Height: 50mm

Pole number: 6

The linear motor core is usually composed of silicon steel sheets. The main function of silicon steel sheets is to reduce magnet losses and eddy current losses. Silicon steel sheets have good magnetic permeability and low magnetic permeability, which can effectively conduct magnetism and reduce energy loss in linear motors. Silicon steel sheets are usually stacked, bonded, and processed to ensure the efficient operation of linear motors. Parameters such as the thickness and magnetic permeability of the silicon steel sheet are selected according to the design requirements of the linear motor to ensure the performance and efficiency of the motor.

Linear motor cores are widely used in electronic and semiconductor equipment, photovoltaic lithium battery industry, UV inkjet printing industry, precision CNC machine tools, high-end medical equipment, mobile phone testing industry, glass testing industry and other fields.

OD24mm Brushless Bldc motor rotor and stator laminated iron core stamping DC for Industrial control

Stator OD | Stator ID | Number of slots |

| 24mm | 5mm | 7 |

Pole width | Material | Height |

| 3mm | B50A600 | 30mm / 40mm / customized |

Inquiry Now

Inquiry Now

OD24mm Brushless Bldc motor rotor and stator laminated iron core stamping DC for Industrial control

Stator OD | Stator ID | Number of slots |

| 24mm | 5mm | 7 |

Pole width | Material | Height |

| 3mm | B50A600 | 30mm / 40mm / customized |

Generally speaking, the role of core injection molding is to comprehensively protect, insulate and improve the overall performance of the motor, making it more suitable for operation in different environments and working conditions. This process is usually used for core protection in motors, transformers and other equipment to ensure long-term stable operation of the equipment.

Inquiry Now

Inquiry Now

Generally speaking, the role of core injection molding is to comprehensively protect, insulate and improve the overall performance of the motor, making it more suitable for operation in different environments and working conditions. This process is usually used for core protection in motors, transformers and other equipment to ensure long-term stable operation of the equipment.

New energy / automotive motor cores, Yuma Precision currently has rich project experience in the development of automotive motor cores. At the same time, we have cooperated in the development of new energy pure electric/hybrid vehicle drive motors, compressor cores, and automotive power steering motors, automobile oil pump motor core, window motor core and other dozens of automotive products. It has rich experience in cooperation and development, and combines iron cores with rubber-coated parts to optimize the product structure.

Inquiry Now

Inquiry Now

New energy / automotive motor cores, Yuma Precision currently has rich project experience in the development of automotive motor cores. At the same time, we have cooperated in the development of new energy pure electric/hybrid vehicle drive motors, compressor cores, and automotive power steering motors, automobile oil pump motor core, window motor core and other dozens of automotive products. It has rich experience in cooperation and development, and combines iron cores with rubber-coated parts to optimize the product structure.

248mm OD High quality industrial motor rotor and stator laminated iron core for Textile machine

| Outer diameter | Inner diameter | Pole width |

| 248mm | 170mm | 12mm |

| Number of slot | Skeleton | Material |

| 24 | NO | B35A300H |

Compared with the traditional structure, it is characterized by the direct drive structure, which can reduce the energy saving of the motor by more than 20%.

Inquiry Now

Inquiry Now

248mm OD High quality industrial motor rotor and stator laminated iron core for Textile machine

| Outer diameter | Inner diameter | Pole width |

| 248mm | 170mm | 12mm |

| Number of slot | Skeleton | Material |

| 24 | NO | B35A300H |

Compared with the traditional structure, it is characterized by the direct drive structure, which can reduce the energy saving of the motor by more than 20%.

New energy vehicles are undoubtedly the direction of subsequent development of the automotive industry. Yuma Precision Intelligent Manufacturing Park has injected sufficient power into the new energy industry; currently we have been involved in various types of automotive pumps, automotive spindles, air conditioning compressors, electro-hydraulic pumps, and EPS steering. Motors, booster motors, pure electric/hybrid drive motors, window motors and other automotive fields. In the future, we will devote more energy to accelerating global manufacturing and achieving a green future.

At present, Yuma is involved in the automotive field → pure electric drive motor, hybrid P1/P2/P3 drive motor, automotive water pump/oil pump motor, EPS steering motor, gear selector motor, compressor, window motor

Inquiry Now

Inquiry Now

New energy vehicles are undoubtedly the direction of subsequent development of the automotive industry. Yuma Precision Intelligent Manufacturing Park has injected sufficient power into the new energy industry; currently we have been involved in various types of automotive pumps, automotive spindles, air conditioning compressors, electro-hydraulic pumps, and EPS steering. Motors, booster motors, pure electric/hybrid drive motors, window motors and other automotive fields. In the future, we will devote more energy to accelerating global manufacturing and achieving a green future.

At present, Yuma is involved in the automotive field → pure electric drive motor, hybrid P1/P2/P3 drive motor, automotive water pump/oil pump motor, EPS steering motor, gear selector motor, compressor, window motor

Complete in specifications NEMA14-NEMA34 Welcome to inquire

Yuma Precision continues to develop stepper series products, currently including 14 / 20 / 28 / 35 / 36 / 39 / 42 / 57 / 60 / 86 series. Provide customers with ample model choices.

By using rotary lamination, the problem of the same plate difference on the material is eliminated, and the parameters such as the parallelism, flatness and the dynamic balance of the rotor with lateral run out of the product can reach the ideal effect of the customer. At present, and the annual production is nearly 35 million sets. More than 300 customers choose and build long-term and stable relationship with Yuma.

In the research and development of new products, Yuma will continue to optimize the tooth shape / groove type / inner hole of products accordin

Inquiry Now

Inquiry Now

Complete in specifications NEMA14-NEMA34 Welcome to inquire

Yuma Precision continues to develop stepper series products, currently including 14 / 20 / 28 / 35 / 36 / 39 / 42 / 57 / 60 / 86 series. Provide customers with ample model choices.

By using rotary lamination, the problem of the same plate difference on the material is eliminated, and the parameters such as the parallelism, flatness and the dynamic balance of the rotor with lateral run out of the product can reach the ideal effect of the customer. At present, and the annual production is nearly 35 million sets. More than 300 customers choose and build long-term and stable relationship with Yuma.

In the research and development of new products, Yuma will continue to optimize the tooth shape / groove type / inner hole of products accordin