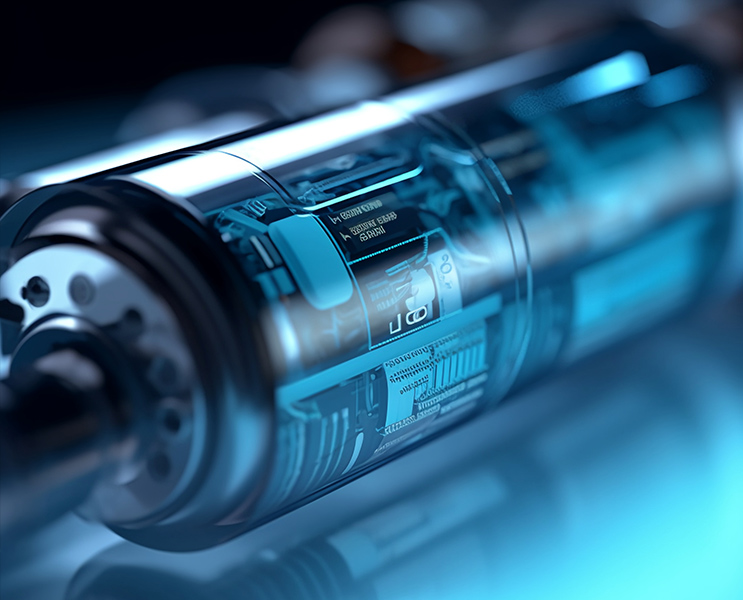

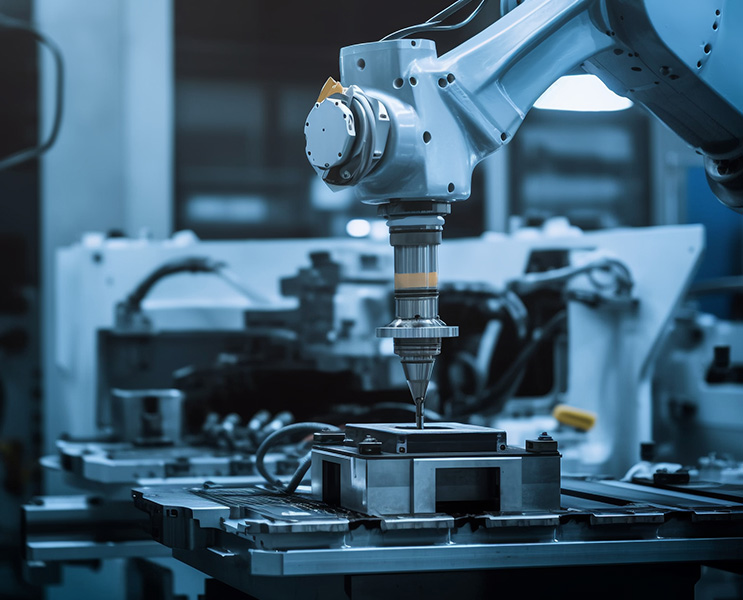

Iron core injection molding is a common protection process for motor parts. Its main functions include:

1. Insulation protection: Injection molding provides effective insulation protection for the iron core. This helps prevent the core from coming into direct contact with moisture, dust and other contaminants in the external environment, thereby preventing the insulation properties of the motor components from degrading.

2. Anti-corrosion: Injection molding can prevent the core surface from being corroded to a certain extent. This is especially important for motors used in humid environments or harsh climate conditions, and can extend the service life of the core.

3. Mechanical protection: Injection molding can provide additional mechanical protection and protect the core from external shock and vibration. This helps prevent the core from being deformed or damaged, improving the durability and reliability of the motor.

4. Reduce noise and vibration: Injection molding has a certain sound-absorbing and buffering effect, which helps reduce the noise and vibration generated by the motor during operation and improves the smooth operation of the motor.

5. Improve insulation performance: The injection molding material itself usually has good insulation performance, so it can improve the overall insulation performance of the motor and reduce the risk of insulation breakdown.

6. Environmental protection requirements: Some injection molding materials have environmental protection characteristics and can meet relevant environmental standards and regulations to ensure that the motor has no adverse impact on the environment during use.

* Support product customization

| Warranty: | 1years | Place of Origin: | Jiangsu, China |

| Brand Name: | YUMA | Model Number: | Stepper Motor Core |

| Material: | Bao Steel | Product name: | servo motor stator and rotor core |

| Certification: | IATF16949 ISO14001 ISO45001 | Application: | industrial control |

| Packing: | Carton + wooden case + desiccant, etc | Item: | FOB |

| Service: | customized | MOQ: | Minimum 1000 sets |

| Delivery time: | 10-15days | Manufacturing Type: | Manufacturer |

YUMA Precision Technology (Jiangsu) Co., Ltd.

YUMA Precision Technology (Jiangsu) Co., Ltd.