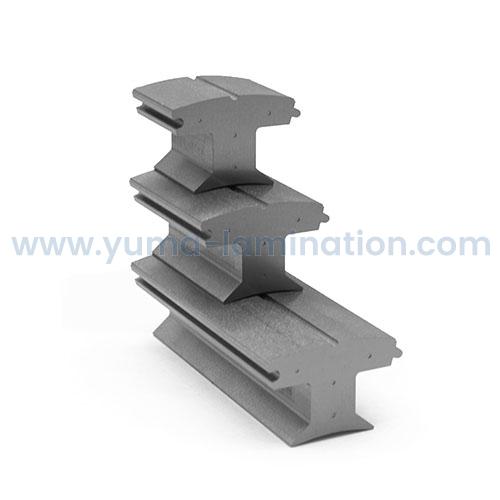

Stepper Motor Core

From the perspective the difficulty of stamping process of stator and rotor core, the production scheme of the stepper motor iron core stamping is undoubtedly one of the series with the highest comprehensive difficulty in the stamping industry. Under the condition that the stamping production of stator and rotor is carried out through zero clearance, the product can achieve rotary lamination at the same time, and finally achieve the micro interference state of stator and rotor, which not only reduces the cost but also meets the needs of customers for the amount of motor wear; And the product after rotation from the form and position tolerance, motor performance has been improved significantly. Yuma Precision continues to advance the development of stepper series. At present, it has 9 series, 33 models and more than 10,000 pieces of materials, providing sufficient model selection for stepper motor standard parts market.