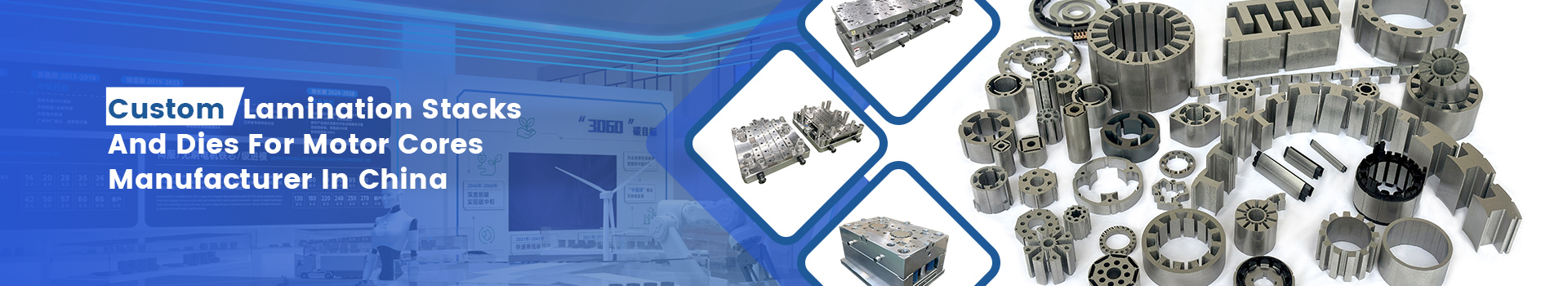

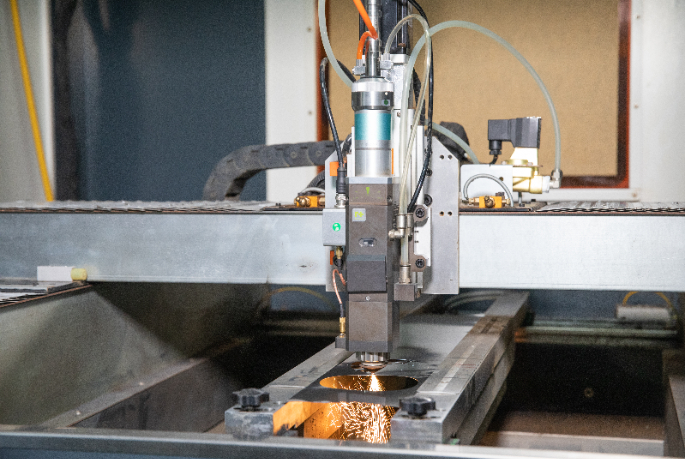

The stamping capability of motor cores is a crucial indicator for measuring the technical level, production efficiency, and product quality of motor core manufacturing enterprises. Stamping capability involves multiple aspects, including equipment performance, process level, material utilization, precision control, and more.