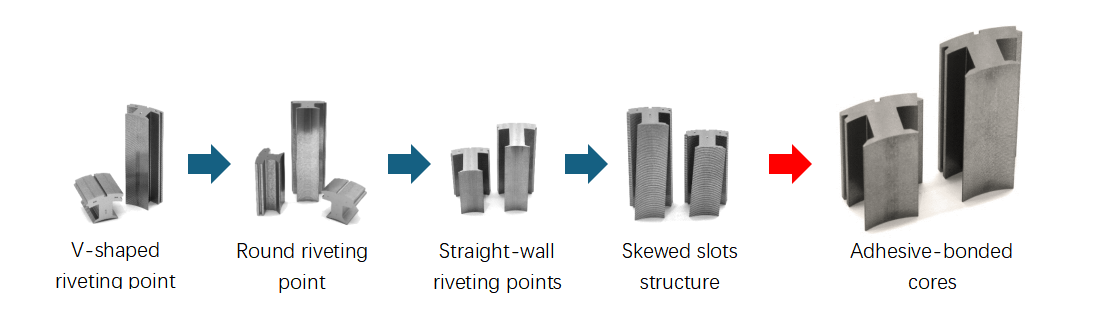

Yuma Precision is specialized in manufacturing segmented structure since 2016. We have evolved from the initial V-sharp interlock to round rivet process, then to straight rivet, while upgrading the structure to skewed groove structure. Each step of trial has significantly improved the product accuracy and motor performance from various aspects.

With the market for motor power density, temperature rise, and vibration has higher requirements, the demand for rivet-free has gradually emerged. After several years of research and development, we have fully mastered the adhesive bonding process for iron cores. The thinnest material currently used in the adhesive process is 0.2mm, and we are now mass-producing silicon steel sheets with thicknesses of 0.2mm, 0.25mm, and 0.35mm.

Advantages of Products/Process

1. High Strength

In the curing process of adhesive-bonded cores, the adhesive can form a strong bonding force on the surface of the silicon steel, which far exceeds of traditional welding or riveting process, thereby enhancing the overall strength of motor cores.

2. High Power Density & Enhanced Efficiency

It usually refers to the ability of a motor to provide a larger power output with a smaller size or lighter weight

3. High Precision

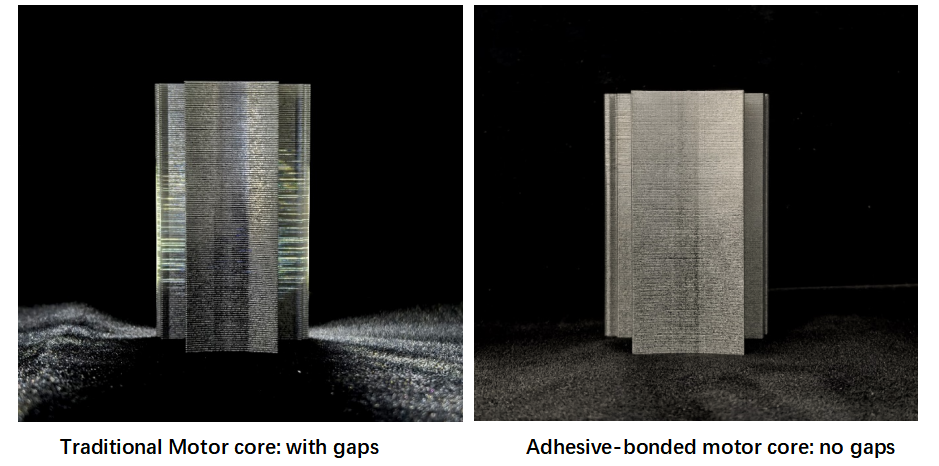

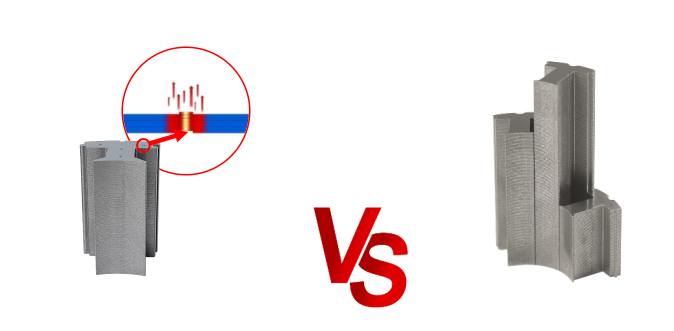

Traditional Motor core: High degree of bending、shrinkage or susceptibility to breakage during manufacturing or usage.

Adhesive-bonded Motor core: Uniformity of surface、planarity and perpendicularity are improved.

4. Vibration & Noise Reduction

Usually refers to the resonance of the motor, which leads to noise.

Adhesive-bonded motor core layers are tightly laminated without gaps. No resonance, thus reducing noise.

5. Temperature Reduction

Traditional Motor core:

Rivet interlock process of motor cores has a significant impact on the motor's temperature. Improper design and stamping process, such as large rivet depth, interlayer damage of silicon steel, location and size of rivets, etc., may lead to additional mechanical stresses, which are converted into heat energy, causing an increase in winding temperature.

Adhesive-bonded motor core:

With good thermal stability and high temperature resistance, compared with traditional welding or rivet interlock, the adhesive-bonded motor core fills the gaps between the laminated sheets, forming a tight structure, which enhances thermal conductivity and helps with motor cooling, reducing temperature.

6. Design Flexibility

Due to adhensive-bonded process, the overall strength of the core is increased, and in design, it can meet extreme requirements.For example, pole width、bridge can be similar to the position of 0.25mm or even narrower.

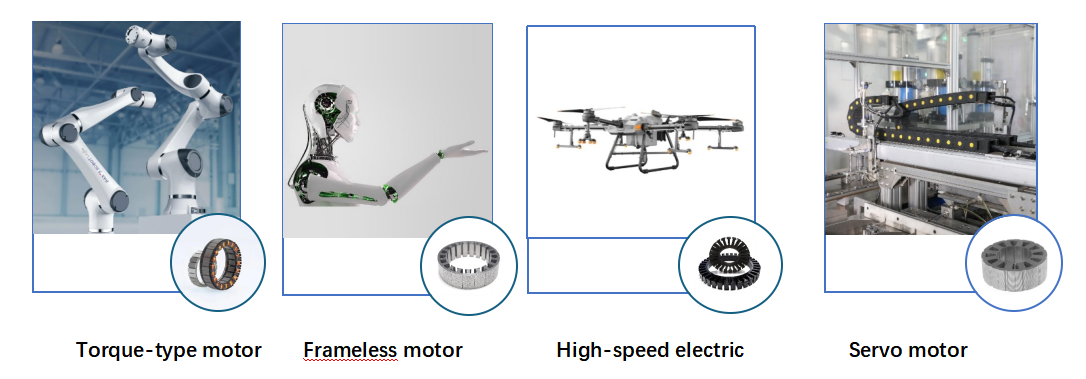

Application