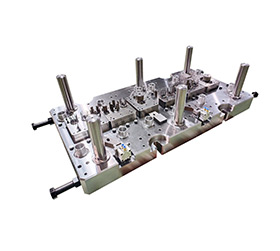

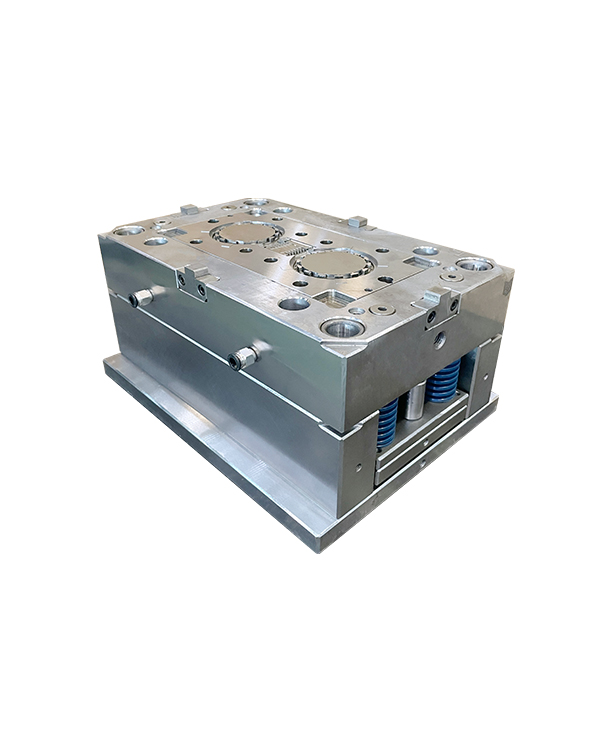

Yuma Precision, as a company specializing in the design, development, and manufacturing of precision molds, has extensive experience and technical expertise in the field of Motor stator and rotor core laminations molds. We can provide customers with complete solutions for Motor stator and rotor core laminations loose sheet molds, Motor stator and rotor core laminations progressive molds, and Motor stator and rotor core laminations injection molds. All molds are independently developed and manufactured to ensure high quality and efficiency.