Sample Development Capability

Yuma Precision, as a professional manufacturer of Motor stator and rotor core laminations molds and motor stator/rotor cores, offers a variety of sample development methods, including laser prototyping, loose sheet mold prototyping, and engineering mold prototyping, to meet customers' diverse needs from design validation to small-batch production. Below is a detailed description of these three prototyping methods:

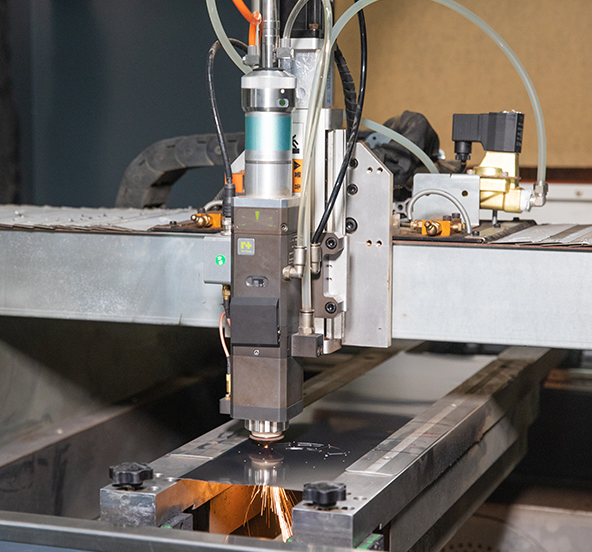

Laser Prototyping

Fast and Efficient

High Flexibility

Low Cost

Applications

Loose Sheet Mold Prototyping

Suitable for Small-Batch Production

High Flexibility

Moderate Cost

Applications

Engineering Mold Prototyping

Suitable for Small-Batch Production

High Precision

Near Mass Production Quality

Fast Transition to Mass Production

Applications

Advantages of Choosing Yuma Precision

Comprehensive Capabilities

Customized Services

Advanced Technology

Rapid Response

Seamless Transition to Mass Production